For hundreds of years, packing has been used to minimize leakage from pumps and rotating equipment. As rotating equipment has evolved, however, so has the need to minimize that leakage even further.

Without some sort of sealing mechanism, process fluid easily leaks out of pumps through the gap surrounding the shaft as it enters the pump housing. For years, pump packing has been used to reduce leakage and minimize the space or clearance between the shaft and pump housing.

The very first patents for mechanical seals appeared in the early 1900s. Since that time, a wide range of seal technology has emerged, ensuring there’s a seal for nearly any application.

There are perks to both mechanical seals and pump packing, so which is right for the application at hand? In this post, we’ll discuss the pros and cons of each.

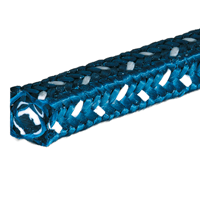

Pump packing comes in many different types and materials. The most common is probably braided compression packing. This type of packing can be made of carbon, graphite, or synthetic materials.

Pump packing comes in many different types and materials. The most common is probably braided compression packing. This type of packing can be made of carbon, graphite, or synthetic materials.

Compression packing is cut to length, formed in rings, and installed in the pump’s stuffing box. The rings are mechanically compressed to reduce leakage.

When the pump is running, liquid enters the stuffing box under hydraulic pressure. The liquid flows under the packing rings and eventually makes its way out of the packing gland. If the packing leaks too much, it can be tightened by the operator or mechanic. Note that the packing’s job is to reduce leakage. Not prevent it entirely.

Pump packing is an inexpensive method of sealing pumps and installs easily. Operators and maintenance teams must determine, however, if these benefits outweigh the disadvantages of packing.

Packing is expected to leak. It is common practice to try to control the leaking to 10-15 drops per minute. To maintain this rate, the packing must be monitored and adjusted daily. The leakage cools and lubricates the packing. Without leakage, the packing will burn and wear grooves into the shaft and sleeves.

Packing is expected to leak. It is common practice to try to control the leaking to 10-15 drops per minute. To maintain this rate, the packing must be monitored and adjusted daily. The leakage cools and lubricates the packing. Without leakage, the packing will burn and wear grooves into the shaft and sleeves.

Over time, packing wears and loses material causing it to leak more than desired. A mechanic or operator must tighten the packing gland again. Adjustments are made frequently and have no set degree of tightening.

Because of this, mistakes are easily made and packing glands are often over-tightened. Over-tightened packing glands oftentimes shorten packing life as the packing overheats and rapidly deteriorates.

Improper packing of the stuffing box can cause rotating equipment to consume more power than mechanically sealed equipment as it works to overcome the friction imparted by packing. Learn more about packing installation in our post "Terms You Need To Know For Packing Installation in Centrifugal Pumps".

Packed pumps and rotating equipment require more maintenance resources as well. This equipment is down more often than mechanically-sealed equipment due to corrosion problems, bearing failures, and shaft sleeve replacements.

Though the packing itself is less expensive than mechanical seals initially, there are other costs associated with this sealing method. Those costs include housekeeping, product loss, and additional power consumption.

Alternatively, mechanical sealing methods can provide many benefits over pump packing. There are many options for mechanical sealing. Single seals are the most common.

Mechanical seals consist of two flat surfaces (materials could include tungsten carbide, silicon carbide, or carbon graphite) compressed by a spring against each other. Just like packing, mechanical seals also require a small amount of leakage. However, the leakage is small, or not noticeable at all.

The pumped product generates a light film of fluid between the seal faces. The film prevents the faces from touching, lubricating them, and absorbing the heat generated from the associated friction. The fluid crosses the seal face as a liquid, then vaporizes into the atmosphere. Single mechanical seals are common practice when the pumped product poses little to no risk to the environment.

Like pump packing, the mechanical seal does leak. But unlike pump packing, in many applications the leakage is so small it’s practically invisible. This means there’s no mess on the floor to cause potential safety hazards. With less leakage, there’s less product loss.

Mechanical seals do not impart friction on the rotating equipment shaft. Therefore, it’s more energy-efficient than packing.

One disadvantage to mechanical seals is the complexity involved with the installation. Proper installation is critical to the long-term success of the seal so it’s important that they’re installed by trained professionals. Check out this blog post we wrote about mechanical seal installation, “5 Ways to Kill A Mechanical Seal During Installation”.

Here’s a video to demonstrate proper installation.

Although mechanical seals require a higher initial dollar investment, when properly applied, they can run for over 10 years without failure or adjustment. When considering the cost of replacing and maintaining packing, installing a mechanical seal will cost less than pump packing over the lifetime of the equipment.

The biggest advantage to mechanical seals over pump packing is the minimal amount of maintenance. Packing requires frequent adjustment and replacement, not to mention the upkeep that comes with constant leaking.

On the flip side, the upfront cost is substantially higher for a mechanical seal over braided packing or other types of packing. Teams must decide for themselves if the maintenance required to properly care for packed rotating equipment is sustainable.

If it’s decided to look into replacing packing with mechanical seals, get an engineer involved to help select the right seal for the application. Seals can be expensive and with hundreds of options to choose from, it’s best to lean on the expertise of someone who frequently selects them.

Need help selecting the right mechanical seal for your process? Ask us about it! We gladly provide technical expertise to manufacturers and municipalities in Wisconsin, Minnesota, and upper Michigan.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.