Air-operated double-diaphragm (AODD) pumps are used in facilities of all sizes, and in a variety of different industries. From petrochemical to food and beverage, these pumps are popular and versatile. Their unique design is ideal for transferring highly abrasive or viscous products. But how do they work?

An AODD pump is a type of positive displacement pump that uses compressed air as a power source. The compressed air is shifted from one chamber to the other by a linked shaft that allows the chambers to move simultaneously. This back-and-forth motion forces liquid out of one chamber and into the discharge piping while the other chamber is being filled with liquid at the same time.

A note about compressed air: when the air leaves the compressor, it’s often wet, dirty, warm, and unregulated. Dirty, unregulated air can damage AODD pumps. To set air-operated diaphragm pumps up for success, it’s important to supply them with the best quality air possible.

A note about compressed air: when the air leaves the compressor, it’s often wet, dirty, warm, and unregulated. Dirty, unregulated air can damage AODD pumps. To set air-operated diaphragm pumps up for success, it’s important to supply them with the best quality air possible.

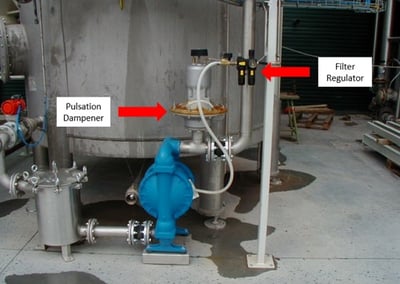

Filter regulators are available to provide air filtration and pressure regulation. This component will remove solid and liquid contaminants and provide clean, controlled, and consistent air pressure.

AODD pumps use reciprocating elastomeric diaphragms and check valves to pump fluid. These flexible diaphragms are made from a wide variety of materials and should be selected based on chemical compatibility first.

The liquid chambers are filled and emptied by fluid that is drawn through a common inlet and discharged through a single outlet.

Air-operated double diaphragm pumps have good suction lift characteristics and can handle sludges or slurries with a relatively high amount of grit and solid content. AODD pumps are also well applied to applications including highly viscous liquids.

Watch the video below to see a visual explanation:

Depending on the type, composition, and behavior of the solids in the pumped fluid, the AODD pump may have ball valves or flap valves. These valves operate using the pressure differences in the pumped liquid.

Flap valves are best for large solids (up to the line size) or solids-laden slurries. Ball valves perform best with solids that settle, float, or suspend.

Another distinct difference between ball valve pumps and flap valve pumps is the suction and discharge ports. In ball valve pumps, suction ports are on the bottom of the pump. In flap valve pumps, suction ports are on top, enabling it to better handle solids.

It is important to note that there is usually some pulsation of discharge flow in air-operated diaphragm pumps. This can cause excess movement in the pumping system. This pulsating flow can be reduced somewhat by using pulsation dampeners in the discharge piping.

Pulsation dampeners absorb energy from the pulse wave created by AODD pumps. They create an area of low pressure in the system with enough volume to absorb the pulsation.

The pulsation dampener has a membrane with a cushion of compressible gas/air behind it that flexes to absorb the pulse, allowing a laminar flow downstream of the dampener.

AODD pumps offer simple technology and reliable pumping for many fluids across many industries. Engineers and experts rely on Crane Engineering for insight and help with AODD, positive displacement, and centrifrugal displacement pumps. Our in-house team of engineers can answer questions related to not only pumps but valves and skid systems. We provide a complete service and repair team who will fix pumps back to OEM standards. We are ready to assist you, contact us, today!

Curious if an air-operated double diaphragm pump fits your application? Watch our webinar or Contact our team of experienced engineers to find out. If you already know what you need, request a quote!

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.