With the wide variety of pumps available today, it’s sometimes hard to know which is best for your specific application. Which can handle the viscosity of the fluid? Generate the proper flow and pressure?

This post will provide a guide to the inner workings and characteristics of internal gear pumps to help determine if they are a good fit for the intended application.

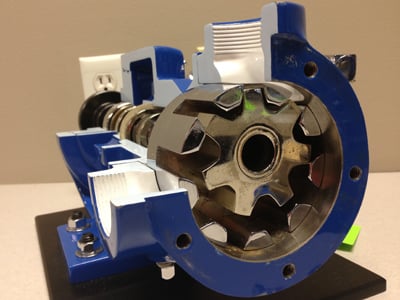

Internal gear pumps are positive displacement pumps. They are very versatile, with the ability to pump fluids at a wide range of viscosities and temperatures. An internal gear pump operates using two rotating gears to move fluid. A rotor gear on the outside and a smaller, idler gear nested inside.

HOW INTERNAL GEAR PUMPS WORK

As the rotor (outer) gear turns, it drives the idler (inner) gear. When the idler gear comes out of contact with the rotor gear, a low-pressure zone is created. The liquid is drawn into the pump and travels along with the casing to the discharge side of the pump. The gear teeth mesh back together and force the fluid out of the pump.

Proper gear clearance is essential to the long life and efficiency of these pumps. If the clearance is too wide, pump efficiency will suffer. If pump clearance is too tight, as in the case of thermal expansion, the gears will make contact and cause damage or failure.

Unlike a centrifugal pump that cavitates against blocked discharge lines, an internal gear pump will continue to generate flow and build pressure. The pressure will continue to build until something releases it. Oftentimes, this results in a pump failure and a costly component repair or replacement.

Internal gear pumps are oftentimes equipped with an internal or external relief valve. This valve diverts flow when pressure builds in the discharge line, preventing catastrophic failure.

BEST APPLICATIONS FOR INTERNAL GEAR PUMPS

Internal gear pumps are ideal for high viscosity fluids. This is just a brief list of applications where internal gear pumps can be used:

Internal gear pumps are also great for situations where low NPSH is required. With only two moving parts, they are also low maintenance.

Internal gear pumps do not do well with large solids. Because these pumps are made with small tolerances, large solids can easily damage the pump. They can handle some small, suspended solids in abrasive fluids but be advised that this can cause the pump to wear and lose performance.

Internal gear pumps can become less efficient as fluid viscosity decreases.

In situations where the product viscosity is low and discharge pressure is high, the product can “slip” through the machined clearances in the pump which can cause it to recirculate from the discharge side to the suction side.

In most cases, product slip is an annoyance and an issue for efficiency but can cause bigger problems with certain products that harden when at rest such as chocolate and adhesives. This may cause a need for a suckback.

Expert Internal Gear Pump Insights from Crane Engineering

Engineers and experts rely on Crane Engineering for insight and help with Positive Displacement and Internal Gear Pumps. Our in-house team of engineers can answer questions related to not only pumps but valves and skid systems. We provide a complete service and repair team who will fix pumps back to OEM standards.

If you need help selecting the right pump for your application, ask us about it! Our company provides pumps, valves, parts, and services to customers in Wisconsin, Minnesota, Iowa, North Dakota, South Dakota, and the Upper Peninsula of Michigan. Crane Engineering also builds and designs customized skid systems nationwide.

Let us know how we can help you, request a quote today!

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.