A come-along? Seriously? Our Service Technicians have seen it. Using a come-along, or any other type of force to get pipes and pumps together causes serious pipe strain on the pump, bringing a myriad of other issues along with it.

2. THOU SHALT NOT USE A HAMMER TO POUND ANYTHING ON THE PUMP INTO PLACE

Pounding on a pump to get impellers, couplings or shafts back into place can damage them, while also causing damage to mechanical seals.

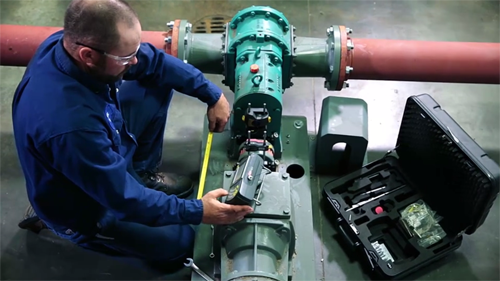

3. THOU SHALT NOT RUN A PUMP THAT HAS NOT BEEN ALIGNED

Misalignment accounts for up to 50% of damage in rotating machinery. Skipping this step can lead to seal and bearing failure, excessive energy usage, and shortened mean time between failure of the pump.

4. THOU SHALT NOT RUN A PUMP WITHOUT PROPER LUBRICATION

Lubricant is the lifeblood of a pump. Be sure it has the correct lubricant, in the correct amount so it functions without seizing or leaking excess lubricant.

5. THOU SHALT NOT IGNORE START UP PROCEDURES IN THE PUMP'S MANUAL

The procedures outlined in the pump's manual are designed to give you the best possible instruction for ensuring a long and trouble-free life for your pump. Read it, and follow each step in the procedure!

6. THOU SHALT NOT COLD START A PUMP WHEN THE FLUID'S VISCOSITY HAS CHANGED DUE TO COLD TEMPERATURES

Following proper procedures when installing a pump is the first step in ensuring the most energy and cost efficient operation possible. Read the manual, train the operators and you'll avoid chronic, costly pump repairs.

Have a pump that may have fallen victim to a broken commandment? Sign up for a Bad Actor Pump Assessment! We will gladly provide a no cost assessment to companies in Wisconsin and Upper Michigan.

These Stories on Equipment Maintenance

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.