It should go without saying that pumping slurry isn’t quite as easy as pumping water. Depending on the type of slurry, there are many variables that go into selecting the proper pump for slurry. There is no formula or cut-and-dry answer as to what the optimal slurry pump design is. You must combine knowledge and application specifics into selecting the ideal slurry pump. Let’s talk about how slurry pumps are different than standard water pumps and how to narrow down your choices.

It should go without saying that pumping slurry isn’t quite as easy as pumping water. Depending on the type of slurry, there are many variables that go into selecting the proper pump for slurry. There is no formula or cut-and-dry answer as to what the optimal slurry pump design is. You must combine knowledge and application specifics into selecting the ideal slurry pump. Let’s talk about how slurry pumps are different than standard water pumps and how to narrow down your choices.

First of all, what is slurry? Slurry is a semiliquid mixture, typically comprised of fine particles. Examples of slurries may include manure, cement, starch, or coal suspended in water. There are countless other combinations that could be considered “slurries”. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard water pump might be able to handle the fluid, but not as effectively as a properly-sized slurry pump.

Let’s consider the impeller. Slurry pumps must have thicker vanes than water pumps to allow for wear and tear. Because of the added thickness, there will be fewer vanes, otherwise the passageways would be too narrow and would hinder the pump’s performance. The impeller should have large enough passageways so that the largest solid particles can pass through without clogging.

Let’s consider the impeller. Slurry pumps must have thicker vanes than water pumps to allow for wear and tear. Because of the added thickness, there will be fewer vanes, otherwise the passageways would be too narrow and would hinder the pump’s performance. The impeller should have large enough passageways so that the largest solid particles can pass through without clogging.

Another important part of a slurry pump is its casing, which handles all of the pressure. Slurry pump casings should have larger gaps between the impeller and the cutwater tongue to reduce wear and to prevent large solid particles from getting stuck. Because of the additional space, there is more recirculation inside a slurry pump casing under various operating conditions. Again, this accelerates wear compared to a typical water pump.

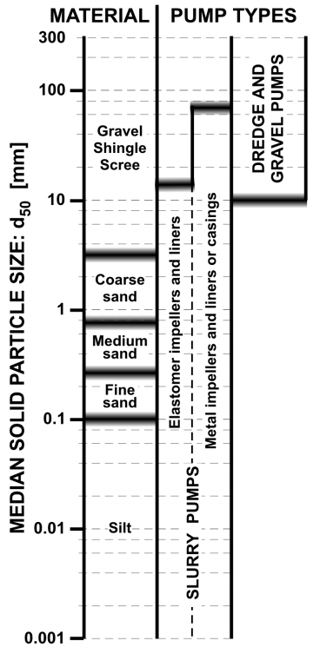

Metal and/or rubber pump liners are used to combat the erosion from the solid particles that are found in slurry. Goulds, for example, offers the XHD (Extra Heavy Duty) Lined Slurry Pump for pumping slurry. This pump is lined with rubber.

Metal slurry pump casings are usually made of hard alloys to resist erosion caused by the increased pressure and circulation. Sometimes wear-resistant steel is used on pump casings so that the pump can be welded if in need of repair.

Remember, slurry pumps are designed to suit specific pumping conditions. Pumps used in the cement industries handle mostly fine particles at low pressures, so the casings can be of light construction. In rock pumping, the pump casing and impeller must resist hard knocks, so they must be built thick and strong.

Slurry pumps also have a provision for simple axial adjustment of the gap between the impeller and the adjoining throatbush seal face. This assists in maintaining pump performance as the inner component parts start to wear.

If you aren’t sure what kind of pump to use in your slurry application, check out our Beginner's Guide to Pumping Slurry or contact us! Our experienced engineers will gladly assist your business in Wisconsin or Upper Michigan.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.