In industrial operations, mixing is rarely the headline. But when it fails, everything downstream feels the impact. Inconsistent product quality, raw material loss, failed batches, line stoppage, bottlenecks, reduced throughput, and production delays can often be traced back to poor mixer selection or non-integrated mixer and vessel designs. That’s why Crane Engineering takes a deliberate, solutions-first approach to mixing—and why we proudly partner with Cleveland Mixer.

Together, Crane Engineering and Cleveland Mixer deliver a combination that customers value most: proven performance, reliable designs, and fast delivery, backed by expert local support. It’s a partnership built to help plants operate more efficiently and respond faster when mixing challenges arise.

Choosing the right mixer is about more than horsepower or tank size. Every process brings its own variables—fluid properties, solids content, tank geometry, operating conditions, and production goals. A mixer that’s undersized, oversized, or poorly matched to the application can lead to long-term operational losses.

At Crane Engineering, we approach mixing as a process problem, not a product transaction. Our team works with engineers, maintenance supervisors, and plant managers to understand what’s happening inside the tank and what the operation truly needs to achieve. From there, we recommend integrated equipment that delivers consistent results, long service life, and strong value.

Cleveland Mixer aligns perfectly with this approach.

Cleveland Mixer has earned a strong reputation across industrial markets for delivering mixers that perform reliably in demanding environments—without the long lead times or premium pricing often associated with larger manufacturers.

Key advantages of Cleveland Mixer include:

For customers seeking dependable mixing equipment that fits both their process and their budget, Cleveland Mixer consistently delivers.

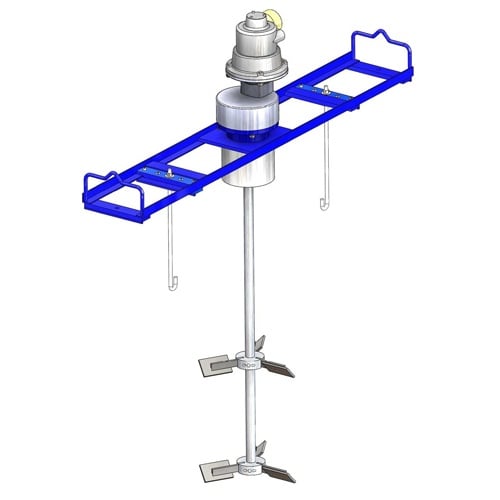

One of the most compelling reasons Crane Engineering recommends Cleveland Mixer is the Eastern Mixer product line. These portable and fixed-entry mixers are designed for quick delivery, making them an ideal solution when timelines are tight.

Eastern Mixer products are well-suited for:

In many cases, long lead times—not equipment performance—are the biggest obstacle to solving a mixing issue. Eastern Mixer’s availability allows Crane Engineering to help customers restore operations faster, reduce downtime, and avoid extended production disruptions.

When speed, reliability, and performance all matter, Eastern Mixer is one of the strongest options on the market.

Cleveland Mixer products are engineered to deliver consistent mixing results while minimizing maintenance demands. Proper impeller selection, mechanical design, and drive configuration help ensure efficient blending, solids suspension, and energy efficiency.

When paired with Crane Engineering’s application expertise, these mixers often serve as an effective replacement or upgrade for aging or underperforming equipment. The result is improved process stability, reduced maintenance frequency, and greater confidence in day-to-day operations.

While Cleveland Mixer provides the equipment, Crane Engineering provides the expertise and support that ensure success.

Our customers rely on us for:

We don’t just supply mixers, we help customers make informed decisions that improve operations over the long term.

In today’s industrial environment, customers are looking for partners who can move quickly, communicate clearly, and deliver reliable solutions. The Crane Engineering and Cleveland Mixer partnership was built around those exact priorities.

By combining Cleveland Mixer’s durable, cost-effective designs with Crane Engineering’s application knowledge and local responsiveness, we provide a smarter, more dependable path forward for industrial mixing challenges.

Whether you need a fast-delivery mixer, a reliable replacement option, or expert guidance on improving your process, Crane Engineering is ready to help.

Talk with our mixing experts today to find the right solution for your operation.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.