Fluid processing is a critical aspect of food, dairy, and beverage manufacturing, where the right pump plays a crucial role in maintaining product integrity, ensuring hygiene, and optimizing efficiency. Selecting the appropriate pump for a specific application involves considering various factors such as the type of fluid being handled, operational requirements, regulatory compliance, and lifecycle costs.

This guide provides a comprehensive overview of key considerations to help you make informed decisions when selecting pumps for food and beverage processing, including options from leading manufacturers such as Fristam, Viking Pump, Waukesha Cherry-Burrell (SPX Flow), Grundfos, and Xylem.

Before selecting a pump for your process, you'll need to identify the specific application and process requirements, including flow rate, pressure, temperature, viscosity, and the characteristics of the fluid being pumped (e.g., viscosity, abrasiveness, shear sensitivity).

Consider factors such as the need for gentle handling of shear-sensitive fluids, the ability to handle solids or particulates without clogging, and the presence of entrained air. Entrained air that isn't mitigated can lead to issues such as cavitation, reduced pump efficiency, and product degradation. If you need assistance with this, our team of engineers is here to help; simply contact us for more information.

In food and beverage processing, hygiene is critical. You should choose pumps with sanitary design features such as smooth surfaces, crevice-free construction, and easy disassembly for cleaning and sterilization.

Leading manufacturers like Fristam, Viking Pump, NETZSCH, and Xylem prioritize sanitary design principles to meet stringent industry standards and regulations, ensuring product integrity and hygiene in fluid processing operations.

The internal surface finish of pumps and processing equipment is also important. Most food and beverage applications have specific requirements regarding the surface finish, typically measured in Ra (roughness average), that is necessary to meet sanitary standards. Common surface finishes include:

Selecting the appropriate surface finish is essential for maintaining product integrity, preventing contamination, and ensuring compliance with regulatory standards in food and beverage processing. If you need assistance, contact us to determine the optimal surface finish for your specific application.

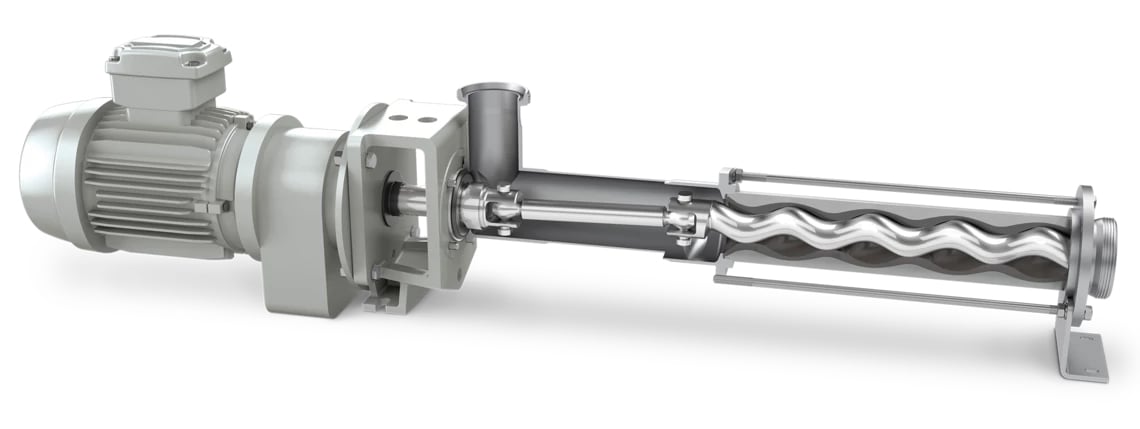

There are various types of pumps for sanitary applications, including both positive displacement and centrifugal pumps. Certain types of pumps offer specific advantages tailored to different applications.

When selecting pumps for your food, dairy, or beverage process, you'll want to consider the energy efficiency of the pumps to minimize operating costs and environmental impact. Look for features such as variable speed drives (VSDs) or efficient motor designs available in pumps from reputable manufacturers, enabling precise control and optimization of energy consumption based on process demand.

Ensure that whatever pumps you choose comply with relevant regulatory standards and guidelines, such as FDA, USDA, 3-A Sanitary Standards, EHEDG, and NSF/ANSI standards for food contact materials.

Before purchasing new equipment, it's always smart to evaluate the total cost of ownership, including initial purchase price, installation, maintenance, and downtime costs over the pump's lifecycle. Brands like Fristam and Viking offer pumps known for their reliability, ease of maintenance, and availability of spare parts, contributing to reduced downtime and operational disruptions.

If you need assistance getting your process set up or require maintenance down the road, Crane Engineering is a factory-authorized service center for Viking Pump, Goulds Pumps, Xylem, Pulsafeeder, and other reputable brands. We can also help you understand what your total cost of ownership would look like for various sanitary pumps.

Seek advice from pump manufacturers or certified distributors like us who specialize in food and beverage processing to ensure you select the best pump for your specific application and requirements. Check out some of our food & beverage success stories, where we helped our customers across the Midwest.

Selecting the right pump for food, dairy, or beverage processing involves careful consideration of application requirements, design and surface finish, material compatibility, efficiency, compliance, and lifecycle costs.

When working with Crane Engineering, you'll have access to sanitary pumps from leading manufacturers like Fristam, Viking Pump, Waukesha Cherry-Burrell (SPX Flow), Grundfos, and Xylem. We will help you optimize your process efficiency, ensure product quality, and maintain compliance with industry standards and regulations.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.