Problems with pumps are rarely caused by the pump itself. Process conditions and human error are far more likely the case. This week, we reached out to the Quality Manager from LobePro pumps for examples of ways others have killed their rotary lobe pumps. Read the list below, then download our new resource, "27 Ways To Kill A Positive Displacement Pump" for even more examples.

If you're pumping fluid that can solidify inside the pump when not in use, be sure to flush the seal before storage. Not doing so will destroy seals and o-rings, not to mention the lobes themselves.

2. NOT FILTERING / STRAINING / SCREENING PROCESS FLUID

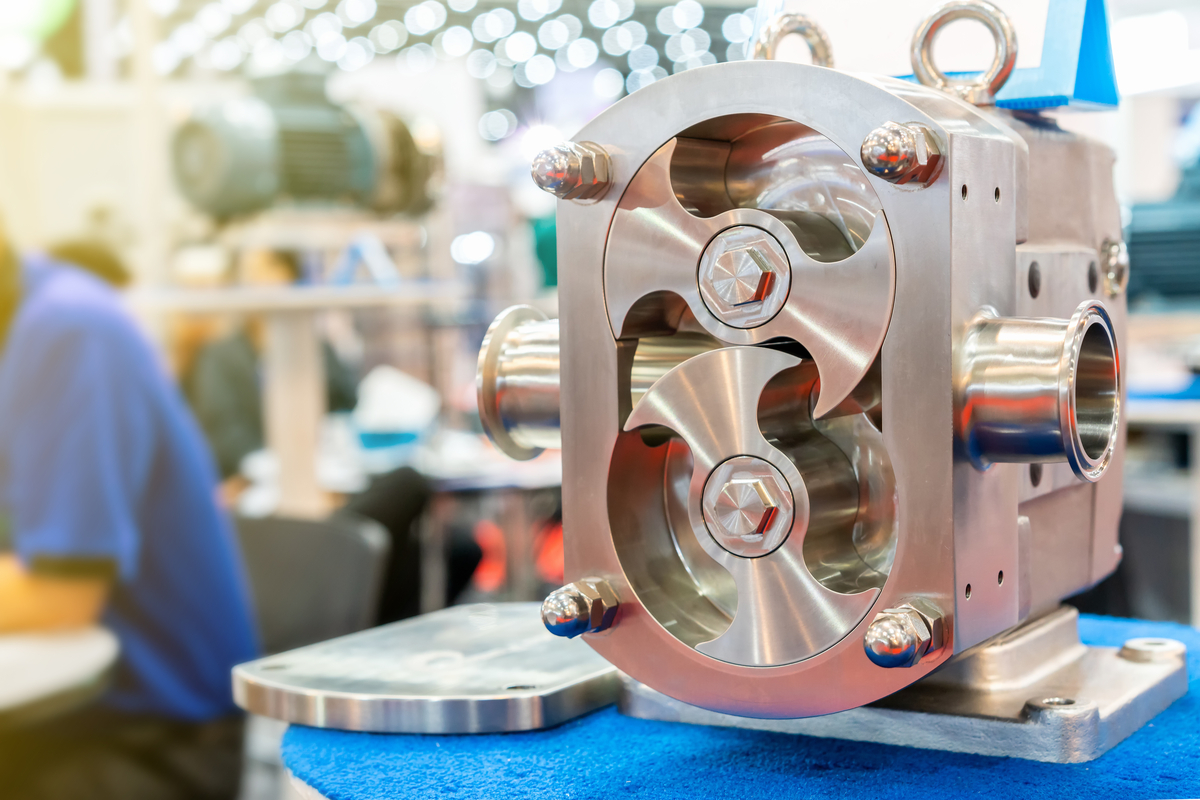

2. NOT FILTERING / STRAINING / SCREENING PROCESS FLUIDYou spend a lot on your pumps, protect them with some form of filtering upstream. In this example, a screen had been in placed, but was removed. Solids got into the process fluid, breaking strain bolts, and destroying the lobes.

Be sure to protect your investment with a strainer, screen, or filter. The initial cost of the equipment is minimal compared to the cost of downtime and pump repair!

3. IMPROPER SCREENING

3. IMPROPER SCREENINGWe talked about the importance of using a screen before the pump, but what's just as important is to make sure it's the right one for your application.

This example shows a lobe with premature wear due to improper grit removal. Early lobe replacement was needed.

4. OVER PRESSURED LIP SEAL

There's no magic bullet for preventing all unnecessary pump repairs. But you can help prevent them by reading the pump manual and training your operators in proper maintenance and installation techniques.

Want to see more positive displacement pump failures? Check out our latest resource "27 Ways To Kill A Positive Displacement Pump"!

Struggling with problem pumps? Ask us about it! We gladly provide technical assistance to businesses and municipalities in Wisconsin and upper Michigan.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.