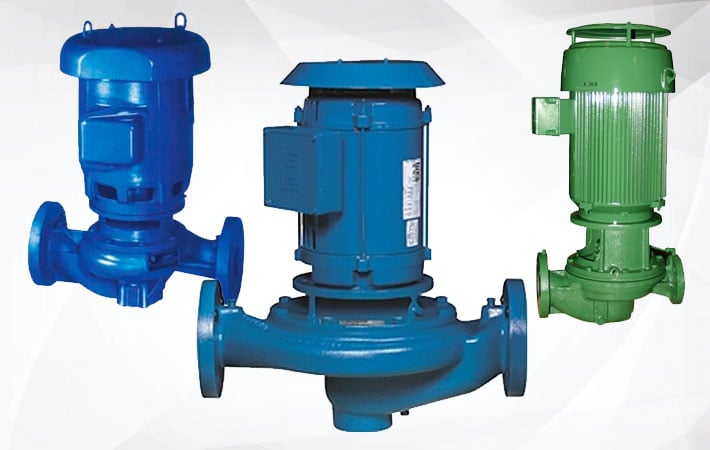

Centrifugal pumps are the most widely used pumps in the world. The vast majority of installed centrifugal pumps are of horizontal configuration. Perhaps in your facility it's the same. But don't discount the vertical inline centrifugal pump. It has some benefits that you might want to consider before selecting your next centrifugal pump.

Centrifugal pumps are the most widely used pumps in the world. The vast majority of installed centrifugal pumps are of horizontal configuration. Perhaps in your facility it's the same. But don't discount the vertical inline centrifugal pump. It has some benefits that you might want to consider before selecting your next centrifugal pump.

Functionally, the two styles are very much the same. They both include an impeller and utilize centrifugal force to move fluids from point A to point B.

Functionally, the two styles are very much the same. They both include an impeller and utilize centrifugal force to move fluids from point A to point B.

They're both efficient, and are similar in price. The biggest difference between these two pump styles is pretty obvious, the vertical or horizontal shaft positions.

Though the horizontal shaft position is far and away the most popular, the inline configuration definitely has some benefits over horizontal. Here are some reasons why an inline centrifugal pump might be your next best selection.

Before you dial up your nearest pump distributor for an inline pump, there are a few cons to consider:

If space is a concern now, or could be in the future, take a look at the inline centrifugal pump. It will deliver near equal performance to an end suction pump at a fraction of the footprint. Talk to an engineer experienced in fluid process equipment to learn if this change would work for your process.

Not sure if an inline centrifugal pump is right for you? Ask us about it! We gladly provide technical assistance to businesses and municipalities in Wisconsin and upper Michigan.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.