Lately, we’ve been getting a lot of questions about fugitive emissions. The EPA has been cracking down on fugitive emissions violations, and regulations are becoming more and more stringent. When you read about how dangerous fugitive emissions can be, like the major gas leak in Aliso Canyon, it’s easy to understand why.

Although your facility most likely isn’t leaking enough natural gas to fill the Rose Bowl, even small leaks pose threats to the health of workers, communities, and are even costing your company money.

Fugitive emissions are the unintended release of gases or vapors into the air due to pressurized equipment leaks, or other unintended releases of gas.

Fugitive emissions pose an array of threats to workers, communities, and the environment. Volatile organic compounds, or VOCs, from oil refineries and chemical plants are particularly dangerous. These leaks can also increase the risk of fire and explosion.

Here you can see methane emissions from valves in an oil and gas operation.

When looking to stop fugitive emissions, your valves should be the first place you check. It’s unclear just how much valves contribute to overall gas and vapor leaks, but most reports agree, it’s at least half.

When looking to stop fugitive emissions, your valves should be the first place you check. It’s unclear just how much valves contribute to overall gas and vapor leaks, but most reports agree, it’s at least half.

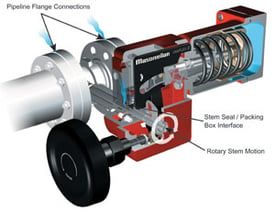

The type of valve employed is key to controlling emissions. Rotary valves, such as ball and butterfly, are inherently better suited for maximizing stem sealing and minimizing fugitive emissions. Their design makes them far superior for controlling emissions over linear acting valves. However, in industries like oil and gas, where the greatest amount of fugitive emissions occur, linear acting valves have been the historical valve of choice.

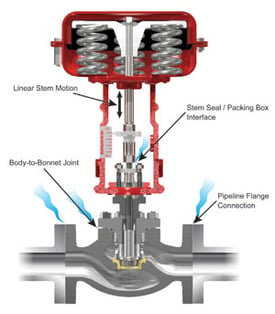

These images from Valve Magazine show leak paths for globe valves and rotary control valves.

Of course one of the quickest and best ways to stop fugitive emissions is to replace old and outdated valves with new designs that seal better. But that’s not always in the budget.

If replacing every valve in your facility isn’t in the cards for you, ensure your valves have proper packing and stem sealing. This will greatly reduce emissions.

Another way to reduce emissions is to ensure valves have been properly installed. Installation in the incorrect orientation, or along pipes that are improperly supported can also be a source of leaks for valves.

Not only do fugitive emissions cost companies money by means of product loss, they can also cost big bucks in EPA fines, environmental risks, health hazards, legal liability, and plant shutdowns.

When selecting a valve to control emissions, be sure to talk to a qualified valve engineer who can help you find the right design and materials to minimize risk.

Need help selecting valves to control emissions in your facility? Ask us about it! We gladly provide technical assistance to businesses in the U.S.

These Stories on Valves

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.