Did you know that pressure pulsation from your centrifugal pump can cause damage to your system? Pulsations can be very destructive for certain equipment and machinery. In this post you will learn how you can combat these pulsations with one quick fix; a staggered vane impeller.

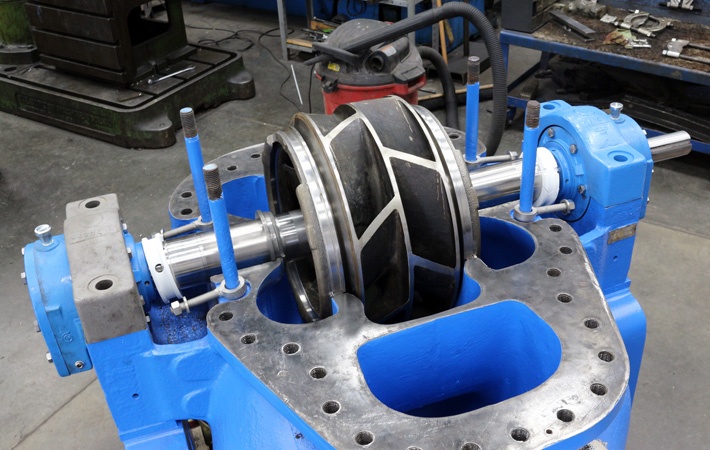

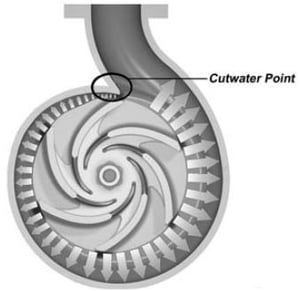

A staggered vane impeller has split vanes and the two sets of vanes are offset from one another. This type of impeller was designed to decrease pressure pulsations when pumping. Pulsations occur in centrifugal pumps when each vane passes the cutwater. This action could be described as quickly closing and opening a valve every time a vane passes.

The impeller is the most significant factor in pressure pulsations. Geometry is one of the most important parts of the impeller because when the vanes of the impeller are staggered, only half the width of the vane passes at a time. That means part of the vane passes the cutwater twice as many times as it would if it wasn’t staggered and the volume of each vane holds half as much. Because of the increase in vane passes and the decrease in vane volume, the pulsations overall that the pump experiences have a lower magnitude but a higher frequency.

The impeller is the most significant factor in pressure pulsations. Geometry is one of the most important parts of the impeller because when the vanes of the impeller are staggered, only half the width of the vane passes at a time. That means part of the vane passes the cutwater twice as many times as it would if it wasn’t staggered and the volume of each vane holds half as much. Because of the increase in vane passes and the decrease in vane volume, the pulsations overall that the pump experiences have a lower magnitude but a higher frequency.

The staggered vane impeller is often used in large double suction centrifugal pumps. They first began using them in the paper industry where it is extremely important to have low pressure pulsations. Many of the machines used to make paper cannot handle high pressure pulsations so the quality of paper was being effected. To solve this problem, they implemented the staggered vane impeller and it has been in use ever since. It is not only used in the paper industry, but it is also used in any application where pulsation magnitude needs to be lowered.

Although having little to no pulsation is always preferred and this impeller would solve that issue, these aren’t right for every application. Tests have shown that having a staggered vane impeller slightly decreases the efficiency of the pump. When deciding whether this impeller is right for you, there are many different factors to take into account, including allowable pressure magnitude, pressure frequency, and efficiency required.

If you think your application might benefit from a split vane impeller, contact us. We'd love to analyze your system and help make proper adjustments.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.