No one is more familiar with clogged pumps than our friends in the wastewater treatment industry. Flushable wipes, sanitary items, and a wide variety of miscellaneous objects can be a constant source of frustration.

Pump manufacturers have added all kinds of cutting devices to help prevent clogs. Chopper, cutter and grinder pumps all have the ability to break up solids, but which one is best for your process? Here's the break down on each.

Chopper pumps are generally used for applications prone to severe plugging. A chopper pump is a centrifugal pump fitted with a fixed set of cutting bars, and a rotating element mounted externally at the pump suction. This set up allows large objects and solids to be broken up into smaller and more manageable pieces before they enter the pump.

Chopper pumps are generally used for applications prone to severe plugging. A chopper pump is a centrifugal pump fitted with a fixed set of cutting bars, and a rotating element mounted externally at the pump suction. This set up allows large objects and solids to be broken up into smaller and more manageable pieces before they enter the pump.

Chopper pumps are very effective in handling heavier and harder solids because of their robust design. They have a moderate head and flow range, but the range of operations is less than standard. Due to the need for power and robust design, the chopper pump tends to be the most expensive option.

Although the pump is able chop and pass rags, rags have been known to recombine and continue to cause problems downstream.

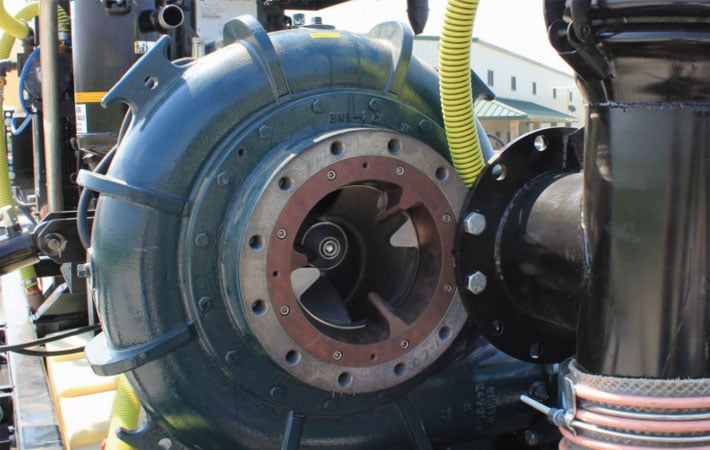

A Cutter pump's job is also to reduce the size of solids. The cutter pump's impeller drives the rotating cutting action while the stationary element is mounted at the pumps suction inlet. The stationary cutter has a ring with cutting teeth or scissor like blades that shred materials entering the pump.

A Cutter pump's job is also to reduce the size of solids. The cutter pump's impeller drives the rotating cutting action while the stationary element is mounted at the pumps suction inlet. The stationary cutter has a ring with cutting teeth or scissor like blades that shred materials entering the pump.

Cutter pumps are typically used to address clogs and rags. They have an advantage over chopper pumps in terms of energy efficiency, and also a wider range of heads and flows.

This type of pump handles rags and clogs well, but has a tougher time with very long ropes of rags and stringy material.

Read: Sick of Ragging? How One WWTP Put The Kibash On A Rag Plagued Pump

Grinder pumps utilize a rotating cutting device at the inlet, resulting in a fine slurry. Grinder pumps are usually found in lower-flow applications.

Grinder pumps utilize a rotating cutting device at the inlet, resulting in a fine slurry. Grinder pumps are usually found in lower-flow applications.

Most grinder pumps are submersible and run at higher speeds. They are usually installed at the source of the supply to the main sewage system.

Grinder pumps are able to easily handle some of the toughest materials in the stream, but at a cost. These pumps have a narrow head and flow range and use a large amount of energy compared to a standard submersible pump.

Not sure which style of pump to choose? Ask us about it! We gladly provide technical assistance to businesses and municipalities in Wisconsin and upper Michigan.

These Stories on Pumps

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.